You might have in mind why Corrugated Roofing Sheets. A recent trend toward modernistic, low-cost solutions and a general desire to branch outwards from expensive roofing forms has led to a singular change in roofing industries worldwide. This change is the popularity of Corrugated Roofing Sheets, a pre-built roofing material that takes the stress out of a job.

However, if you’re considering using corrugated roofing sheets for your building, taking the time to learn more about these phenomenal materials will definitely pay off in the long run. That’s why below, we’re going to explore everything you need to know about corrugated roofing sheets.

What Are Corrugated Roofing Sheets?

Corrugated roofing sheets are a low-cost alternative to cement-and-brick roofs, mostly found in agricultural buildings, warehouses, and other large commercial structures. These roofing sheets feature repetitive folds on their surface, giving them added reliability and durability for years to come. It also makes them noticeably stronger than flat roofing sheets, making them popular in areas where weather and pollution cause frequent damage to roofing.

Benefits like that have made corrugated roofing sheets a popular sight in Southeast Asian, West European, and Midwestern American regions, where frequent rainfall and heavy (and rising) pollution breaks down most metal roofing in just a couple of years.

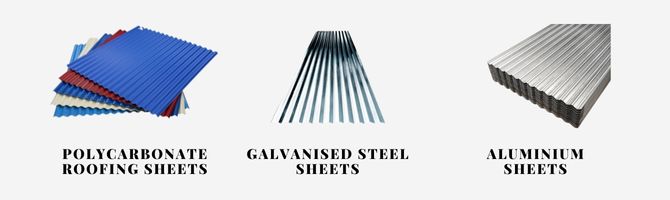

What Materials Are Used for Corrugated Roofing Sheets?

- Polycarbonate Roofing Sheets: One of the friendliest materials for roofing sheets is Polycarbonate roofing sheets. These are lightweight and durable, and their polycarbonate construction makes them resistant to damage from harsh UV rays as an added bonus. The best thing about them, however, is that they are very inexpensive to purchase, set up, and maintain over a period of decades.

- Galvanised Steel: Galvanised steel roofing is slightly less popular, but if taken care of properly, it can be almost as durable as its polycarbonate brethren. This major advantage is their solid construction and aesthetic, making a building look more significant than polycarbonate roofing. However, keep in mind that depending on the pollution level, these have to be cleaned, maintained, and sometimes repainted every 5-10 years.

- Aluminium: Aluminium rests solidly between the previous two options as an all-rounder material. It’s flimsy and lightweight, but the corrugated shape of these roofing sheets enables even aluminium to endure decades of weather and pollution damage. As an added benefit, it’s also more widely available from a more significant number of providers, allowing you to pick and choose the quality of roofing sheets you want.

What Are the Benefits of Corrugated Roofing Sheets?

Corrugated roofing sheets get a lot of advantages from their unique structure, a list of facts that go from being stronger than flattened roofing sheets to even being resistant to UV damage from harsh rays. Here are some of the things that make these sheets such prolific roofing solutions:

- They are stronger: Their unique rippled structure makes corrugated roofing sheets much stronger than other types of roofing. This also makes them better for covering smaller surface areas than flat roofing.

- They can be tailor made: The best thing about corrugated roofing sheets, however, is that they can easily be tailor made into any designs, shapes, and sizes you need. That means easy, low-cost roofing for any structure of any size.

- They are UV resistant: Believe it or not, one of the largest sources of damage to roofing sheets is UV radiation from harsh sun rays. This effect is seen more in places where the ozone layer has been damaged due to pollution. Polycarbonate roofing sheets are made to be UV resistant, which means they are easily usable for more than decades.

- They are impact resistant: A rippled structure is better at distributing the impact of falling objects, making these roofing sheets popular in climates with frequent hail and heavy rainfall.

- They require little maintenance: An uneven surface means there’s no chance of solid debris, liquids from rainfall, and other common pollutants pooling on top of the roofing sheets. This means maintenance can be as infrequent as once every 5-10 years and even further apart for polycarbonate materials.

- They are easy to set up: Roofing sheets, whether corrugated or not, are a much easier option to set up than regular roofing. In the case of corrugated roofing, it’s as simple as picking out the type you want, choosing the size and shape that’s perfect for your structure, and having it installed for a marginal fee.

What Are Some Common Applications of Corrugated Roofing Sheets?

As mentioned before, corrugated roofing sheets are used in industrial areas, where structures need to be efficient, durable, and yet low-cost enough to keep overheads within operating margins. Their unique construction makes sure industrial buildings like warehouses and garages are durable, and it also helps that they don’t require frequent maintenance.

With that said, here are a couple of the most common places where you can expect to see corrugated metal roofing:

- Agriculture: These roofs provide the best protection against strong winds, heavy rainfall, and other such weather conditions, which makes them perfect for agricultural storage buildings like barns and silos. However, they can be hard to acquire in rural farmland areas, so you’ll mostly see them in farms near major cities.

- Vehicle Storage: Remember when we said these roofing sheets are often used for garages? Huge warehouses in industrial sectors often convert leftover space into low-cost parking structures with prefabricated walls, floors, and corrugated metal roofing.

- Warehouses: The overall objective when constructing a warehouse is to build a structure within a certain budget that will be long-lasting and durable. Combined with that is the need for low required maintenance, as having a team of workmen in the warehouse can disrupt operations. Since corrugated roofing sheets require maintenance only once every 5-10 years, they fit the bill perfectly!

How Roofing Sheet Weight Can Impact Your Structure

If you’re having trouble deciding which type of corrugated roofing sheet is best for you, consider the weight of the sheets first. Polycarbonate sheets are generally the lightest, followed by aluminium and then galvanised steel. It’s important to consider this because the roofing sheets’ weight can adversely affect the structure.

That means you should be sure your structure can support the weight of the roofing sheets. Polycarbonate or Aluminium is the best choice for flimsy prefabricated warehouses, but use galvanised steel if you’re worried about keeping your energy costs low.

Finding The Corrugated Roofing Sheets That Are Right For You: The Takeaway

Given the sheer popularity of these roofing solutions, it’s no surprise that there are hundreds of providers around the world. This also means it’s important to choose one that will provide high-quality roofing solutions at reasonable costs, which might be harder than you think.

On the other hand, it might not be! If you’re looking for a reputed corrugated roofing sheets company, check out JP Industries. It is considered one of the best manufacturers of corrugated roofing solutions today, the sheets you buy from us are guaranteed to be lightweight, durable, and inexpensive! The best part is that Jp Industries is a full-service provider, which means they’ll work with you to find the type of corrugated roofing right for you.